Products

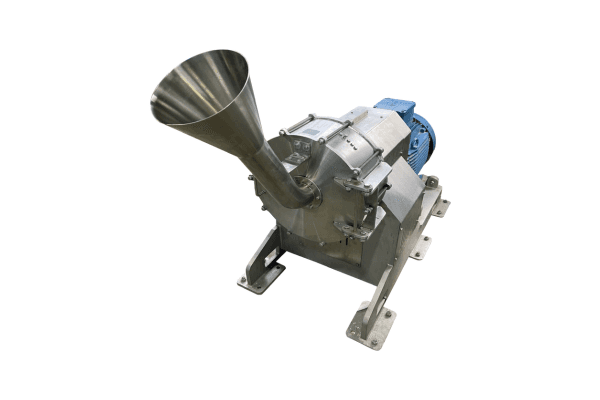

Vortair 500 model is a food grade stainless steel construction with all surfaces glass bead blasted or the option of polished surfaces and safety vibration control and interlock door system are included.

The machine rotor is made of food grade titanium alloy and fully balanced and supported on hi tech silicon carbide angular contact ball races protected by non-contact labyrinth seals. The rotor is driven by a 55kW electric motor geared via a toothed pulley belt drive. The low friction ball races and ‘no contact’ seals allow for rotational speeds up to a maximum of 10,000 RPM at which chaotic air flows are produced to create the autogenous grinding conditions and the resultant particulate sizes. Motor speeds are controlled by an electronic variable speed drive which provides continuous control and readings of power, current, speed, frequency and temperature.

This data is displayed on a HMI panel mounted screen located on the front of the stainless steel electrical cabinet containing the VSD and all isolating and vibration sensing equipment. The system is provided fully assembled and tested, ready to be installed.

Detailed Specifications

Grinding Rotor

Titanium Monocoque Rotor

Drive Shaft

Geared Ratio Pulley Drive System

Drive Balancing

Fully Balanced Rotor & Drive System

Construction

All Food Grade Stainless Steel

Weight

1300KG

Power

55kW 3/50/415v

Speed

Variable up to 10,000 rpm

Vibration Sensing

Drive shaft vibration sensors

Safety Interlocks

Electrical door interlock sensors

Control Panel

Digital HMI System

Product Options

01

Vortair 500 Autogenous Grinder

Water Cooled Model

Vortair 500 Water Cooled model is a food grade stainless steel construction with all surfaces glass bead blasted or the option of polished surfaces.

Water cooled rotor housing and safety interlock door system are included. The machine rotor is made of food grade titanium alloy and fully balanced and supported on hi tech silicon carbide angular contact ball races protected by non-contact labyrinth seals. The rotor is driven by a 55kW electric motor geared via a toothed pulley belt drive. The low friction ball races and ‘no contact’ seals allow for rotational speeds up to a maximum of 10,000 RP Mat which chaotic air flows are produced to create the autogenous grinding conditions and the resultant particulate sizes. Motor speeds are controlled by an electronic variable speed drive which provides continuous control and readings of power, current, speed, frequency and temperature.

This data is displayed on a HMI panel mounted screen located on the front of the stainless steel electrical cabinet containing the VSD and all isolating and vibration sensing equipment. The system is provided fully assembled and tested, ready to be installed.

02

Vortair 500 Fully Polished Surfaces

Option

The standard glass bead blasted surface finish of the Vortair 500 model meets all food hygiene standards however by maximising the surface smoothness by polishing the surfaces are easier to clean and less prone to bacterial growth. To achieve these smoother surfaces, stainless steel components must undergo both electropolishing and mechanical polishing to ensure optimal hygiene.

03

Vortair Cyclone & Dust Extraction

System

The Vortair Cyclone and Dust Extraction System is designed and engineered specifically for the Vortair 500 autogenous grinder to maximise throughput, easy collection of milled powder material and collection of super fine dust particles.

The cyclone is made from food grade stainless steel (SS 316) and is hard plumbed in SS316 piping to our high flow rate centrifugal fan that is then is hard plumbed in SS316 piping to our HEPA filter that has a collection tray for superfine dust particles. The Cyclone features a rotary valve for easy collection of the milled powder material.

04

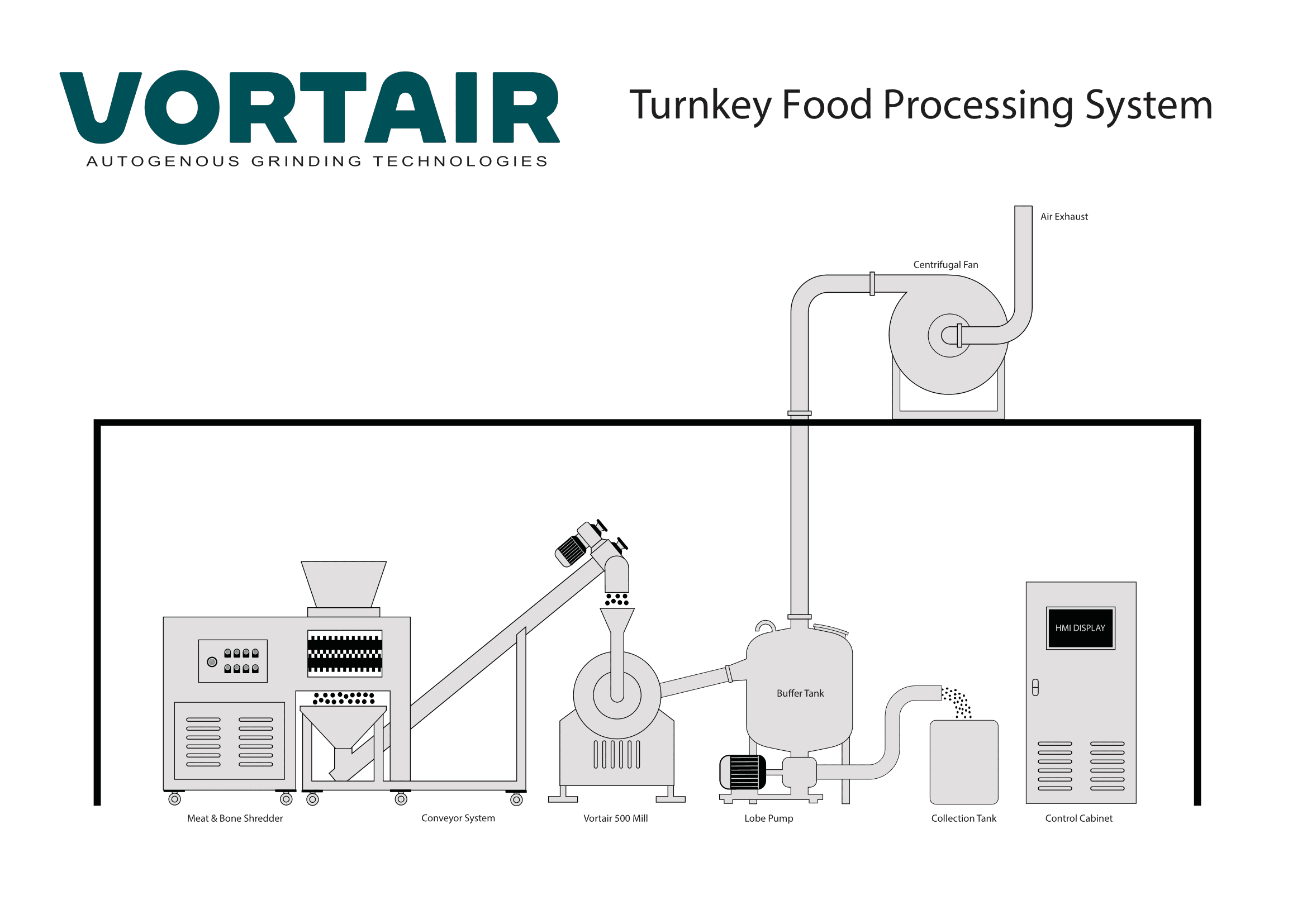

Vortair Turnkey Food Processing

System

The Vortair food processing system is designed and engineered specifically for the Vortair 500 water cooled autogenous grinder to maximise throughput, easy collection of processed food material in a continuous automated production line.

The ancillary equipment: shredder, conveyor, buffer tank, centrifugal fan, lobe pump and collection tank are all made from food grade stainless steel (SS 316) and is hard plumbed in SS316 piping. The Vortair turnkey wet processing system includes digital control of the automated production line through VSD control of feed rates and easy to use HMI system.

05

Vortair Turnkey Powder Processing

System

The Vortair powder processing system is designed and engineered specifically for the Vortair 500 autogenous grinder to maximise throughput, easy collection of milled powder material in a continuous automated production line. The ancillary equipment features an automated feed hopper; conveyor , water chiller. Cylone with rotary valve and dust extraction are all made from food grade stainless steel (SS 316) and is hard plumbed in SS316 piping.

The Vortair turn key Powder processing system includes digital control of the automated production line through VSD control of feed rates and easy to use HMI system.